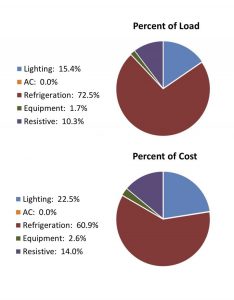

Cooling and refrigeration systems typically account for 60%-80% of a grocery store’s electric consumption. Lighting comprises another 10%-20%. Addressing these two areas can yield substantial savings and benefits to a store’s operational cost and consumption.

A grocery store has a complex energy use profile. HVAC, refrigeration and food storage, air flow, high and variable public occupancy all are key factors. Comprehensive analysis allows accurate projections of how much savings and benefit can be achieved in the major areas of electric consumption.

The store wide breakdowns illustrated here clearly illuminate the dominance of refrigeration in the overall energy profile. And this predominant energy intensive area’s systems run 24/7/365, regardless of season and store hours, with only moderate dependence on external temperatures. Thus, efficiency enhancements focused on refrigeration provide a very short payback period.

Lighting is the other major consumer of power in a grocery store. Upgrading from fluorescent to LED technology can save 50%-60% of the electricity spent on Lighting. Smart controls, sensors, interconnectedness of luminaires and controllers, and more, provide additional savings. Quality of the Lighting, and the indoor environment will be dramatically improved as well.

Solutions

Refrigeration and cooling systems can be treated in several ways to enhance energy performance. Electric compressor and condenser fan motors can run more efficiently, distribution losses can be minimized, operating temperatures made cooler, where electrical treatments are called for. Specialized lubrication of these loads can be another contributor to improved performance while reducing consumption.

Thermal heat transfer in the refrigeration cycle equipment can be enhanced with several technologies. These products are often bundled together, or can be deployed independently. Virtually every closed loop cooling system based on refrigeration cycles with a refrigerant as the heat transfer agent can benefit from getting more cooling capacity from less power.

Especially in large stores and food processing and handling plants, these leading edge technologies, working together, can be effective. Refrigerant lubricants, high efficiency coil coating, evaporative cooling, and other products all enhance performance and minimize duty cycles and power draw.

Likewise, real time Power Quality solutions for the electricity distribution system as a whole may be appropriate in larger operations.

Lighting is, in most locations, running every day for 10 – 14 hours. Ceiling and area luminaires have certain properties to be considered. Cooling and Freezer Case lighting have their own special requirements. Controls can be important as well.

Data gathered , collaboration, and engineering analysis determine which among these will be most effective, and suitable for the systems operating. Climate controlled food product distribution centers and supply hubs stand to reap meaningful benefits from these operational energy optimization solutions as well!

More information about our various technologies, and how they are typically deployed in different types of grocery and food storage facilities, can be found on our Systems page.