Our process and overall approach is collaborative, data-centric, performance based, and comprehensive. We accompany you from first engagement though project completion and MnV. We commit to diligence and perseverance in identifying reductions, efficiencies, savings and optimizations that can be implemented and verified in your facility.

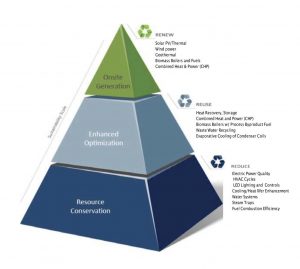

Our approach is founded on performing an initial assessment and engineering analysis in order to baseline the facility. Considering the entire set of potential optimization and efficiency measures within your facility, we then craft solutions targeting the foundation initially, reducing consumption and waste, then advance to successively higher tiers of optimization towards comprehensive solutions. The energy savings measures (ECMs) designed and deployed rely on these pyramidal structured principles as a framework.

ONSITE GENERATION TIER: Once the facility systems are modified and treated to use energy efficiently, Renewable Energy deployments can be effective; less generation is required, reducing the investment in renewable energy production.

ENHANCED OPTIMIZATION TIER: Energy consumption and demand management, minimizing duty cycles by harnessing accessible energy, combined with recycling measures to reuse post-process wasted resources and thermal energy, with significant lifecycles.

RESOURCE CONSERVATION TIER: Efficiency measures and raised utilization of power and resources, combined with the implementation of ECM equipment and processes, to reduce the consumption pattern; Analysis and optimization of the power and resource distribution systems and attached equipment and uses, stabilizing network performance and improving power and resource quality and yield.

Our process accompanies you from initial engagement through post-install verification.

INITIAL ASSESSMENT –

We will meet with you, learn about your physical plant and operations, conduct a walkthrough of your facility to gather information about:

- Key equipment and operations assets.

- Maintenance, Repair and Operations (MRO) process.

- Power and Resource usage and distribution networks.

- Electrical, gas/fuel and water bills and their impact on the production process.

- KPI’s, expected savings, operation and maintenance objectives, production status and targets, and financial performance objectives.

Based on this walkthrough, and the data gathered, we will prepare an Initial Assessment which will contain recommended energy efficiency and conservation measures, estimated cost savings and payback period. There is no fee or obligation for the Initial Assessment.

ENGINEERING AND DESIGN STUDY –

The next step is to prepare an in-depth Engineering & Design Study. The key steps in this process are comprehensive data collection and analysis of opportunities where and how energy and resources can be saved, recovered, utilized more efficiently:

- Inspection and mapping of the electrical, HVAC, steam, compressed air, process fuels, and water distribution systems.

- Measuring and/or recording operating data for all major loads or systems in the facility.

- Identification of process improvement measurements obtained at various locations, considering their interactions.

- Analysis of savings, reductions, and improvement opportunities and selection and placement of appropriate energy conservation measures (ECMs) and resource optimizations to provide cost-effective solutions.

- Computer modeling to simulate system-wide performance with proposed ECMs in your facility.

Based on this in-depth analysis, we will prepare a project proposal including detailed conservation measures, projected savings, reductions, and benefits, fixed price point, and scope of overall integrated project.

INSTALLATION –

Throughout the preparation to execute the savings measures, we work closely and collaboratively with you to plan suitable logistics, scheduling, equipment needs, in order to install the necessary technologies in your facility.

- Coordinate all installation work with an on-site customer authorized representative.

- Installation is performed by licensed professionals according to applicable codes, regulations and facility-specific safety and operational requirements.

- Progress milestones and stages are agreed upon collaboratively, and monitored to ensure proper and successful project management and completion. We endeavor to be as unobtrusive as possible.

MEASUREMENT AND VERIFICATION –

Measurement & Verification (M&V) is critical to assuring our customers that energy savings and performance and power quality benefits are being delivered. We offer a structured, periodic, and customized M&V procedure and schedule with every project. We retain experts who are trained and certified in the International Performance Measurement and Verification Protocol (IPMVP).

We continuously monitor the project to verify energy savings fulfillment and performance, and expected functional behavior of all measures and technologies deployed. We strive to become a trusted and ongoing resource and source of expertise, helping you optimize your power.