Water and Hydronic Systems serve several different purposes in a modern commercial or industrial setting. These include forced hot water heating, chilled water to cool hot motor loads and equipment, precise temperature controlled water temperatures as part of a production process; water towers and distribution for chilled process or domestic water, and more.

Efficiency of the chilling or heating process can of course be a factor in overall system performance, and cost of operation. Too often overlooked as an energy critical performance metric, Water Quality itself can have dramatic affects on thermal conductivity and dispersal to targeted areas. Dirty and/or inconsistent water flow reduces heat transfer, clogs and degrades components such as valves and sensors. This creates inconsistent performance, compromised piping and infrastructure, high cost of operations, and inordinate repair and replacement expenditures. Health and safety concerns related to Water Quality are important as well.

Through an array of methods and technologies, many of these aspects of Water System performance can be improved and rendered far cheaper to operate and maintain.

The following three technologies are frequently bundled together, providing significant savings in many commercial and industrial systems. The suite includes:

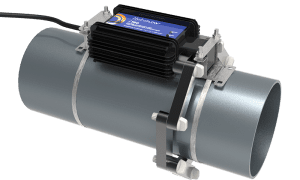

Physical Water Conditioner (PWC) – A non-intrusive external piece of equipment attached to the outside of a pipe that provides a chemical-free solution preventing accumulation of scale and biofilm inside a hydronic system. It gradually removes existing deposits, inhibits corrosion, algae, and bacteria growth. The PWC uses a ring of ferrites to induce a robust, yet harmless, signal of 150 kHz directly into the water that propagates throughout the system, regardless of piping material. The induction of the signal prevents scale and biofilm from accumulating inside plumbing systems and gradually removes existing deposits. These suspended contaminants are now easily filtered out of the system, eliminating and preventing minerals and biofilms from plating out on piping and heat exchanger surfaces.

Coalescing Air and Dirt Separator (CADS) – A retrofit media that is installed directly in a tangential air separator tank. Fine 304 stainless steel wire, constructed into large mesh coils, form a media that occupies <2% of the tank volume. In a closed loop system CADS media coalesce (combine), capture, and remove all entrained air and 99.5% of dissolved air, along with removing particles down to 5µm in size.

Refrigerant Oil Enhancing Lubricant – In systems where Chilled Water systems include refrigerant based cooling cycle equipment, the thermal transfer capability can be improved with this specialized refrigerant lubricant. This is as true for water chilling systems as it is for HVAC-R systems, described on our HVAC, Chilling and Refrigeration page.

Industrial and Commercial Water Meter Pre-Processing – A Hydro Powered Auto Adjusting plumbing device that is installed into your water system that fights against the sporadic water flow delivered to you by the utility. From the water meter on it is the Pre-Processing’s job to protect your facility from that sporadic flow and distribute a more stable flow throughout your facility.

Installed independently, or in tandem with some of the above technologies, it effectively regulates or eliminates –

- Incoming Pressure Spikes

- Turbulent Flow

- Entrained Air Pockets

- Inaccurate Water Meter Readings

- Over Delivered Pressure & Flow

And delivers –

- Savings expectations between 5% and 10% nominally, higher as volume increases

- Self-adjustment to variable flow and conditions

- Short paybacks of 1-2 years

All of these technologies contribute to improving the performance of your water as a resource, and your water systems performance, in terms of the energy and costs needed to achieve the operational requirements of your plant. Taken in combination, depending on the physical, operational, and financial parameters of the facility and business, dramatic reductions in consumption and cost can be achieved.