Description

West Fraser Timber Co. Ltd., founded in 1955, is one of the largest lumber producers in North America. The company’s facility in Arkansas was experiencing widespread Maintenance, Repair, and Downtime Operations (MRO) issues, which metering revealed were caused by poor power quality and unreliable voltage levels. In addition, the company was very keen to lower operating electric bills for their air compression, sawmill, and kiln equipment.

West Fraser Timber Co. Ltd., founded in 1955, is one of the largest lumber producers in North America. The company’s facility in Arkansas was experiencing widespread Maintenance, Repair, and Downtime Operations (MRO) issues, which metering revealed were caused by poor power quality and unreliable voltage levels. In addition, the company was very keen to lower operating electric bills for their air compression, sawmill, and kiln equipment.

The custom, dynamic power quality enhancement system designed & installed by EIS produced over 33% more savings than guaranteed and resolved the facility’s longstanding power quality issues, resulting in considerable MRO savings from decreased downtime and equipment failures. Savings results were verified by CLEAResult for Entergy’s energy efficiency incentive program, which paid for the project.

Savings Summary

actual projected

Mean Annual Cost Savings – Power Quality: 6.67% 5%

Mean Annual Cost Savings – Compressed Air System: 23% 15%

Annual Cost Savings: $227,000

Technologies Deployed

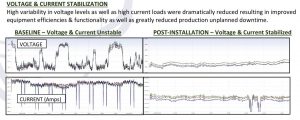

Static and Dynamic Power Quality Treatments. These treatments alone stabilized the voltage in the network, and allowed the transformer tap settings to be reduced by 3 levels, or 7.5%; Compressed Air System Upgrades; Lighting Upgrades

Operational Benefits Observed, Beyond Energy Savings

- Nuisance motor trips and phantom PLC alarms were virtually eliminated

- VFD failure rate was drastically reduced

- Unplanned downtime was reduced by 23%

- Operational KPI metrics of cost per production unit were drastically improved