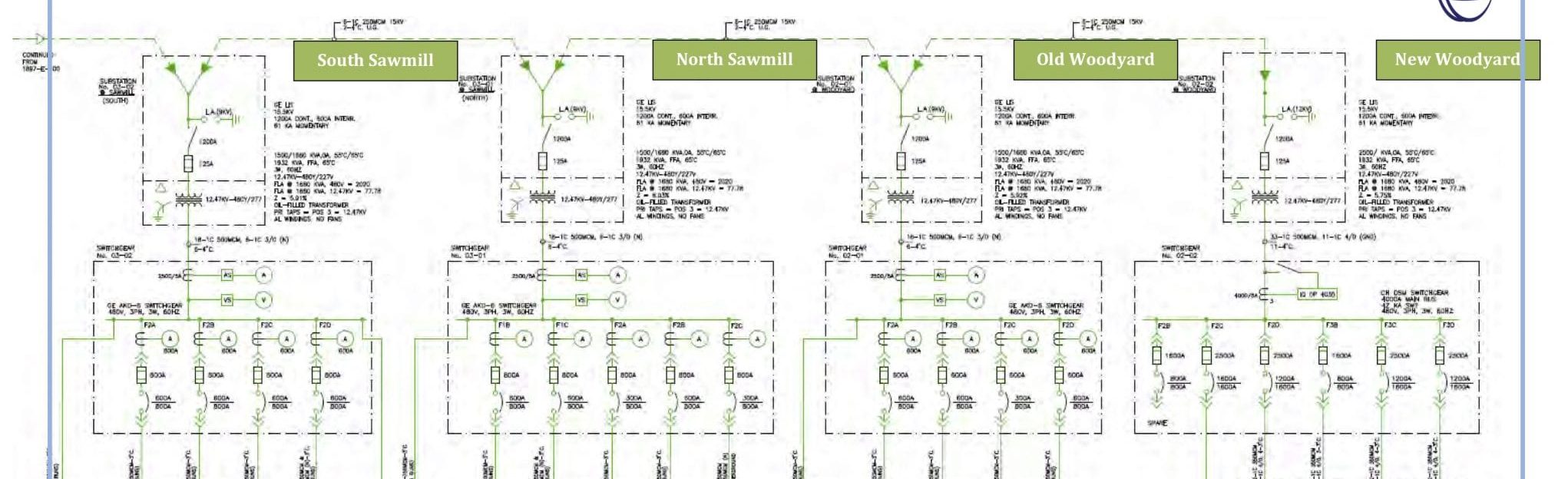

Managing and maintaining a healthy electrical distribution network is critical, and presents a challenging task. Multiple production locations – saw mills, planer mills, kilns, chippers – may be on the premises, with potentially multiple transformers and switch gear sites. A vast array of motor loads, drives, controllers, chippers, steam and air systems, and other equipment create a very dynamic and power and demand profile.

Issues such as voltage instability and sags, current and/or voltage unbalance, elevated harmonic levels are characteristic of such distribution systems. VFD failures, PLC alarms and circuit trips, poor motor performance, and mechanical stresses and failures are all indicators of power quality issues. Such phenomena degrade from everyday operations in often unobserved ways.

Solutions

Real time Power Quality enhancement systems. Installed at the main service points and/or the central distribution panels, our family of Power Quality solutions monitors and rectifies a broad host of electrical parameters, stabilizing the network, eliminating distortions, fluctuations, losses and inefficiencies.

The results of this type of Power Quality improvement will be observed in many aspects of a mill’s operations:

- Motor loads will have the torque they require.

- The voltage will be stabilized across the network, allowing transformer tap settings to be set lower.

- Distortions and fluctuations will be eliminated.

- Maintenance and Repair Operations (MRO) time and expense will greatly decrease.

- Production capacity will be enhanced.

More information about our Power Quality Solutions, and how they can provide dramatic benefits to Lumber, Saw, Wood Processing and many other industries, can be found on our Systems page.