At this point in time, the word INFLATION is becoming a very familiar term to everyone in business. This is especially true for companies in the manufacturing and warehousing sectors as it seems that costs are going to escalate in the coming months and possibly years.

Between the Pandemic, when supply chains all but shut down, and the present inflationary squeeze, watching energy and raw material prices almost double over the last year has completely upset all the cost estimates, production schedules, and profit projections that companies rely on.

The cost of electricity, gasoline, heating oil, natural gas, and diesel fuel have all increased. So have the costs for labor, hospitalization and benefit packages for employees. Everyday we’re getting increases across all sectors and there doesn’t seem to be an end to it. On top of this dilemma, the stock markets appear to be going into a downturn – possible Bear market – which is affecting interest rates and investments.

Recently an article in Utility Dive News stated that:

Electricity prices jumped 51%, to $80.28/MWh, in the first quarter of 2022 from $53.30/MWh in that period a year ago in the PJM Interconnection wholesale market, partly driven by an increase in natural gas prices…. And in New England, wholesale power costs soared 83%, to $137/MWh, in the first three months this year compared with $75/MWh in the same period last year….1

And in The New Hampshire Bulletin an article titled, Electric prices set to double in New Hampshire, stated:

One of the state’s major utilities is set to double the price of electricity in August, and it’s likely other utilities will be forced to raise their prices, too. The price hikes are being driven by projected high costs of natural gas.2

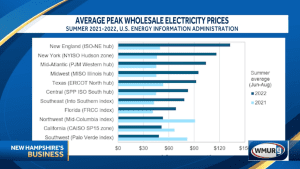

On a recent energy segment on WMUR (Manchester, NH News) this graph was shown – you can see the increases across most of the country in wholesale energy costs compared to last year:

With all of these recent challenges and frightening forecasts, what can a CFO, COO or Plant Manager of a manufacturing facility do to stem the rising tide? Here are a few suggestions that can help in the short and long term.

- The first thing that we recommend is taking a careful look at your energy bills from at least the past 12 months and understanding where you were before and where you are now.

- If you plan to continue manufacturing at the same rate as you have been, you will undoubtedly be losing profit every month going forward unless you make some serious changes.

- The second is to try to conserve energy in the simplest of ways e.g.:

- Shut off and/or control machinery when it’s not being used

- Be sure that all lights and unnecessary energy draining utilities are only used when essential

- Make sure there are no water, air, or other power and resource leaks anywhere in your facility

- Be more conscious of the higher costs to deliver your products and conserve when possible, on things like shipping or freight to save gasoline and diesel oil.

All of these recommendations will also help the environment while saving money across the board. Beyond these immediate measures, it is vital to undertake deeper analysis to discern inefficiencies and opportunities to improve and correct them.

Energy inefficiencies are often “invisible” and therefore not apparent to the leadership of a company. We have found that many plant managers and C-Suite executives are unaware of the unseen, hidden problems within their facilities or equipment that are draining thousands of dollars or more in wasted energy and MRO (maintenance, repair and operations) cost.

Imagine being able to save money by putting off the purchase of some large and expensive equipment for another year or so because it is running more efficiently. Imagine a better bottom line because your use of energy and power have been reduced. How would that improve your business?

Investing in energy efficiency and equipment improvements should be viewed as an opportunity right now. Companies that invest in improving their energy infrastructure are working towards saving money and hedging against Inflation as well as making a positive change for the future. We provide the data, the expertise, and solutions – in short, the opportunity to make your operations better.

Energy LB Resources will evaluate your energy use and provide ways to optimize consumption and yield of power and resources that will increase productivity, save on equipment maintenance costs, impact positively on the environment, and save money for years, offering an attractive ROI on your capital investment.

1 https://www.utilitydive.com/news/power-electricity-prices-pjm-new-england-gas-lng/623724/

2 https://newhampshirebulletin.com/briefs/electric-prices-set-to-double/