Cooling Systems include systems designed for several different purposes in a modern commercial or industrial setting. Air conditioning, refrigeration/freezing of food, beverages, and other perishable items, process chilling of water or chemical solutions for production, and other specialized systems.

The core of most cooling systems continue to relay on the brilliant and effective fundamental refrigeration cycle – capturing thermal energy in one location and placing it in another. This is accomplished by a carefully controlled cycle of injecting a heat transfer medium – a refrigerant – with energy, and transporting it through specific levels of pressure and temperature, affecting phase changes which have the desired thermodynamic affects of absorbing and releasing heat. That said, the materials, chemicals, motors, have evolved radically. Control units and monitoring devices are ever smarter. This is also true of associated equipment in modern systems – Air Handlers, Energy Recovery Units (ERUs), Economizers, etc – and their respective designs.

Many products and technologies exist for enhancing the cooling capacity of modern systems, and improving overall performance. Higher thermal efficiency means reduced operation to achieve the desired set points and operational parameters. temperature and air flow, among others. Reduced operation means less cost.

A suite of four technologies providing thermodynamic savings for HVAC-R systems is called TempShield. The suite includes:

High Efficiency Coating – Environmental damage and corrosion cause an efficiency loss of 3-5% a year in the normal operation of air-cooled HVAC-R equipment by degrading the condenser coils. With HEC, further coil degradation is stopped, and the damaged fin-to-tube connection is repaired restoring the efficiency of the unit. The HEC is made from a thermally conductive material developed using a blend of graphene, carbon nanotubes (CNT), and a specialized polymer, protecting the soft metals from corrosion, environmental damage, and fouling. By leveraging the thermal properties of graphene, the HEC provides complete protection while ensuring the retention of the coil’s heat exchange capacity. The smooth surface of the HEC also inhibits mold and mildew growth while preventing the build-up of dirt and grime, thus reducing maintenance costs.

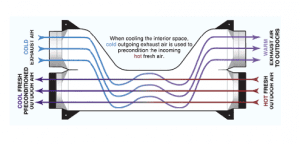

Energy Recovery Ventilators – The ERV is a high efficiency air-to-air heat exchanger that not only recovers sensible heat but also latent heat from exhaust air transferring it to fresh air or vice-versa and doing so without cross contamination between the air streams. The patented counter flow design allows for 80-95% sensible heat transfer and 30-34% latent heat transfer, significantly reducing the energy lost during fresh air exchanges. The ERV is made from medical-grade polypropylene resin that is resistant to many chemicals, bases, and acids as well as prevents the growth of mold and mildew. The special polymer also resists the formation of frost in temperatures down to -20°F without the need for a defroster. The ERV patented polymer construction has no moving parts, requires little to no maintenance, and allows for low pressure drops as well as high-heat and high-moisture transfer. This versatility enables the units to excel at providing comfortable indoor air quality maintaining excellent temperature and humidity control. Energy savings and air quality are simultaneously achieved.

Refrigerant Oil Enhancing Lubricant – The ROEL is a specialized combination of anti-wear and anti-oxidation supplements that significantly increases the lubricity of the refrigeration oil. ROEL is specifically formulated to be compatible with all refrigerants and refrigerant oils, including ammonia, allowing for use in any hermetic or semi-hermetic HVAC-R system. The anti-wear supplements work in two ways, the primary passive while the secondary is temperature activated. The primary passive system seeks out and attaches to metal surfaces creating a thin low friction layer that protects equipment during start up and when harsh conditions cause lubrication failure. The secondary system is a friction activated chemical-polishing agent that restores rough surfaces to a smooth finish allowing for proper lubrication and smooth operation. The anti-oxidation supplements provide 3 times the oxidation and corrosion resistance of traditional refrigerant oil alone, protecting and conditioning internal components such as motors, gaskets, and seals. Also, with the ROEL affinity for metal surfaces it will remove oil fouling in the tubing and coils restoring heat transfer efficiency and refrigerant flow. As a result, the ROEL decreases friction, lowers operating temperature and compressor run times, restores heat exchanger capacity, and overall allows for more efficient operation increasing the useful life of the equipment.

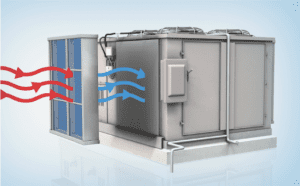

Evaporative Coil Cooling – The ECC is an air-cooled HVAC-R enhancement system that uses evaporative technology to pre-cool air 5-20°F before it passes through the condenser coils, improving system performance and efficiency. By reducing the incoming air temperature to the coils, the ECC system allows the coils to dissipate more heat, increasing the cooling capacity of the unit while reducing operating temperature and pressure. The ECC system consists of an easily attached frame, screen, and filter media with an integrated automatic spray system. The frame is designed to add layers of protection between the condenser coils and the external environment, the filter media prevents any water carryover from the spray system contacting the coils and prevents dirt and debris from collecting on the coils therefore preventing scale buildup, debris fouling, and corrosion of the coils. The automatic spray controller monitors ambient air conditions and media saturation levels optimizing spray frequency and duration, using only a small amount of water needed. In addition to the reduced operating costs and maintenance requirements for the unit, the ECC system also has secure wireless real-time performance monitoring, accessible through the online dashboard. With the dashboard you can monitor system operation, view real time energy savings, and check equipment performance.

Evaporative Coil Cooling – The ECC is an air-cooled HVAC-R enhancement system that uses evaporative technology to pre-cool air 5-20°F before it passes through the condenser coils, improving system performance and efficiency. By reducing the incoming air temperature to the coils, the ECC system allows the coils to dissipate more heat, increasing the cooling capacity of the unit while reducing operating temperature and pressure. The ECC system consists of an easily attached frame, screen, and filter media with an integrated automatic spray system. The frame is designed to add layers of protection between the condenser coils and the external environment, the filter media prevents any water carryover from the spray system contacting the coils and prevents dirt and debris from collecting on the coils therefore preventing scale buildup, debris fouling, and corrosion of the coils. The automatic spray controller monitors ambient air conditions and media saturation levels optimizing spray frequency and duration, using only a small amount of water needed. In addition to the reduced operating costs and maintenance requirements for the unit, the ECC system also has secure wireless real-time performance monitoring, accessible through the online dashboard. With the dashboard you can monitor system operation, view real time energy savings, and check equipment performance.

These technologies can be bundled, or applied independently and/or in combination. The correct solution set for a given Cooling System will depend on the physical and operational parameters of the system, and financial priorities – ROI, overall cost, etc. Baselining of current performance and post-install MnV per the IPMVP Protocol will be undertaken.

With these technologies protecting and cooling the condenser coils, recovering energy from exhaust air, dehumidifying incoming air, enhancing indoor air quality, and improving equipment operations, the TempShield technologies can significantly reduce energy consumption by 20-40% for the operation and increase lifecycle of air-cooled HVAC-R equipment.